System Seals Cracks the Code on Cylinder Optimization

New mathematical tools take the guesswork out of seal design

After more than a year in the research lab, System Seals engineers have developed new tools that precisely measure side-load forces on guide bands. Knowing this, engineers can quickly calculate friction levels and potential for extrusion, while better understanding the unique characteristics of each cylinder.

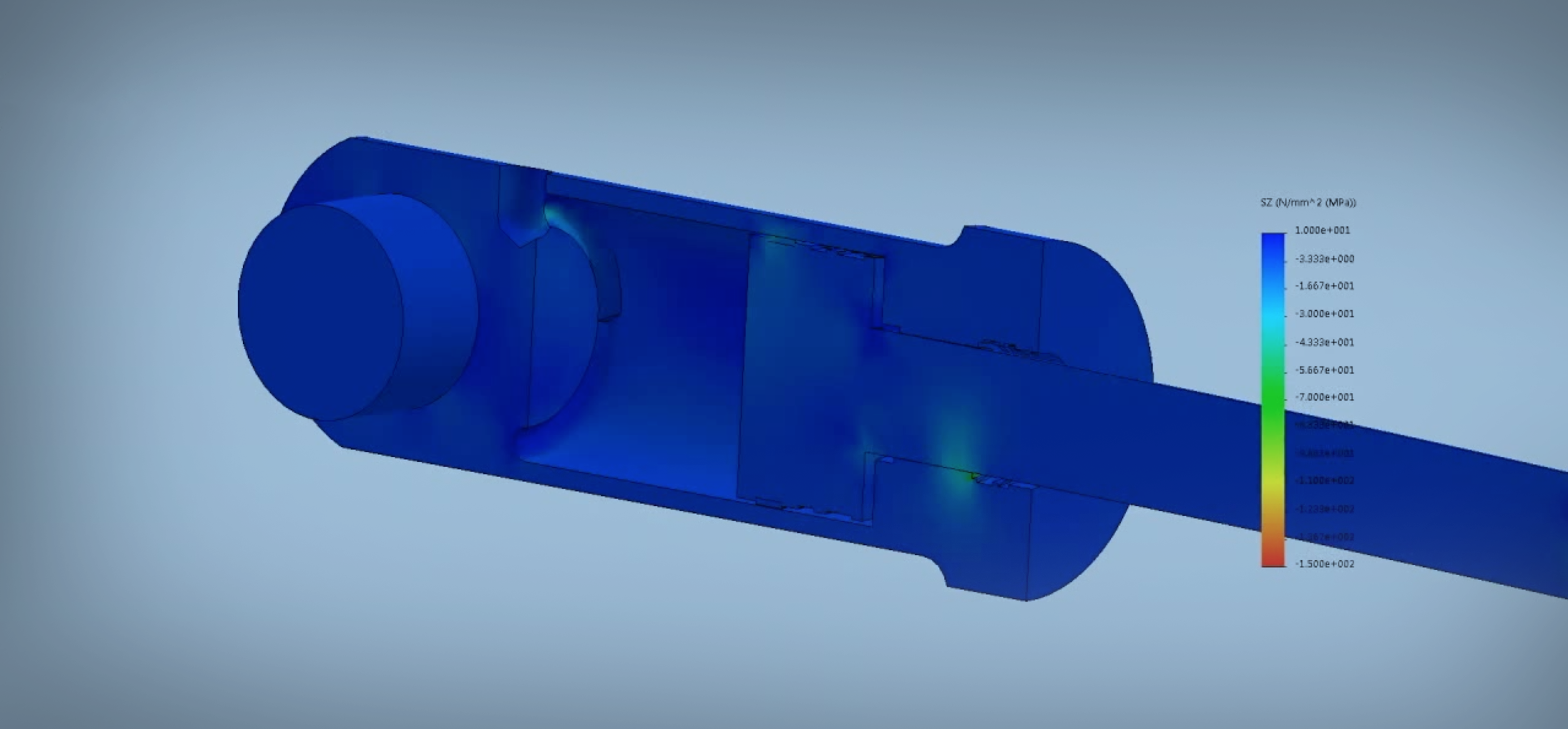

System Seals has rolled the new technology into its Cylinder Optimisation Program – a comprehensive process that calculates a multitude of data to optimise individual cylinders. The process is so precise that in many cases it replaces Finite Element Analysis.

No other company can provide this level of detail, whether it’s an AGC in a steel mill, a forging press or hydraulics on mobile mining equipment. System Seals can pinpoint the side loads and predict how each seal will perform in the long run.

The process ultimately allows System Seals to develop new seal systems that increase uptime, prevent leaks and increase productivity. System Seals engineers also analyse fluid compatibility and surface finish, which is particularly important for uptime in legacy equipment. New seal designs and materials can counteract surface finishes that have become scored over time.

At the end of the process, engineers provide a comprehensive report about each cylinder. The program is completely free, and there is no limit on the number of cylinders that System Seals will analyse.

System Seals’ new side-load calculator measures the precise forces and contact area of the guide bands during side loading. Knowing this information provides a significant benefit on a seal’s design and performance. The new calculator is an integral part of System Seals’ overall Cylinder Optimization Process.

RELATED CASE STUDIES

The new seal performed flawlessly in initial lab tests and then for more than a year in the field. System Seals now produces all new pitch-bearing seals for one of the largest wind turbine manufacturers in the world.

Six-month testing proved the seal to be virtually flawless.

The redesign mitigated financial risk for both the wind turbine manufacturer and owner operator.